Electropolishing

Electropolishing and Passivating

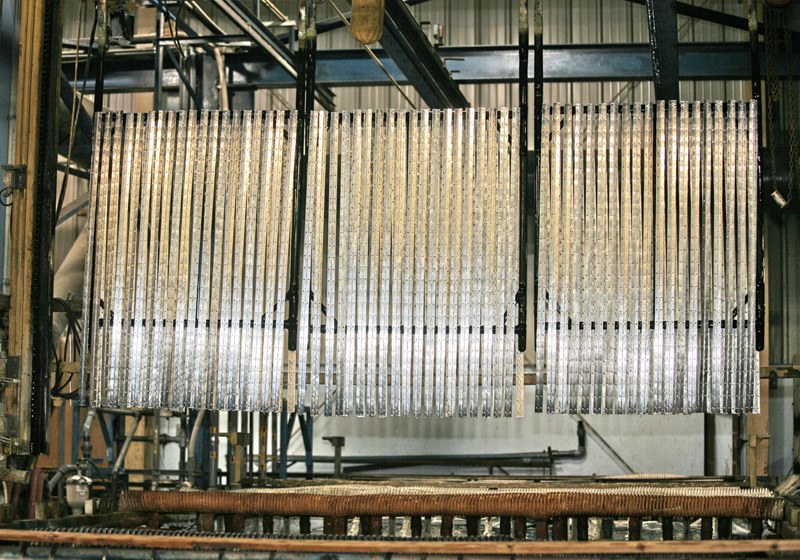

Providing Electropolishing and Passivating capabilities enables Carlsen Precision Manufacturing to control quality and offer very short lead times for products utilizing these processes.

What is Electropolishing?

It is an electrochemical process similar to, but the reverse of electroplating. This electropolishing process smooths out the surface of a metal object by electrolytically removing microscopic peaks of metal.

Comparison to Mechanical Polishing

A mechanically polished metal surface yields an abundance of scratches, strains, metal debris & embedded abrasives. In contrast, the electropolishing process results in a surface which is completely featureless. It reveals the true crystal structure of the metal without the distortion produced by the cold-working process that always accompanies mechanical finishing methods. Electropolishing generally reduces surface roughness readings of a non-electropolished surface by 50 percent and when viewed microscopically it reduces surface area by up to 90% by leveling off the microscopic peaks to a near mirror finish.

Advantages of Electropolishing Over Mechanical Polishing

Better Physical Appearance

No fine directional lines from abrasive polishing, excellent light reflection and depth of clarity, uniform luster of shaped parts, such as the barrel of hinges or formed leaves. Electropolishing simultaneously deburrs as it polishes.

Ease of Cleaning

Substantially reduces product contamination and adhesion due to the microscopic smoothness of an electropolished surface (much like a glass surface). Some companies report that electropolished equipment surfaces have reduced cleaning time by more than 50 percent. The non-stick qualities of an eletro-polished surface improves sterilization and maintenance of hygienically clean areas in hospitals, clinics and food preparation areas. Overall, one can expect a significantly cleaner surface that resists the contaminating buildup of undesirable bacteria and product particles.

Enhanced Mechanical Properties

Less friction and surface drag. Electropolishing reduces the coefficient of friction of metals. The process removes or rounds off the surface microscopic peaks, yielding a coefficient of friction that measures approximately one-fourth of the coefficient registered by a mechanically finished surface. The result is a smoother acting and longer lasting hinge. In addition, the metal surface is stress relieved and retains the true grain structure and properties of the bulk metal. Fatigue strength is not reduced as it is with mechanical polishing.

Best Passivation and Corrosion Protection of Stainless Steel

Electropolishing yields maximum tarnish and corrosion resistance in stainless steel by removing the metallic and non-metallic inclusions that are unavoidably included during manufacturing. These inclusions eventually can become points of corrosion. It has been demonstrated that machined parts of electropolished 304 stainless steel exhibit superior corrosion resistance when compared to the same parts fashioned from non-electropolished 316 stainless steel.

Limitations

Electropolishing cannot smear over or otherwise conceal defects such as seams and non-metallic inclusions in metals. In addition, heavy orange peel, pitting and rough scratches are not removed by a practical amount of electropolishing and thus require an initial "cutdown" with abrasives, if these imperfections much be removed.

Standards of Electropolishing

In the absence of published standards for the finish quality of the electropolishing process, Carlsen Precision Manufacturing operates to the following specifications to produce a bright stainless-steel finish equivalent to BHMA 629, which has replaced the US 32 standard. The Ra of the finished hinge or hardware product will be <1/2 of the Ra of the unpolished material. There is no guarantee that the item will be free of surface imperfections. This is because some scratches or indents in the raw material may be too deep to remove with a practical amount of electropolishing. Furthermore, the dimensions of the product could be made "out of tolerance" if the part was electropolished to the point of there being no surface imperfections.

What is Passivating?

It is a process that removes "free iron" contamination left on the surface of stainless steel as a result of machining processes. These contaminants are potential sites which, if not removed, result in premature corrosion of the component. In addition, the passivation process facilitates the formation of a very thin chromium rich oxide film that protects the stainless steel from selective corrosion.

Standards for Passivating

The processes utilized produce hinges and hardware items that are believed to comply with ASTM A967 Standard Specification for the Passivation of Stainless Steel.

Skip to main content

Skip to main content